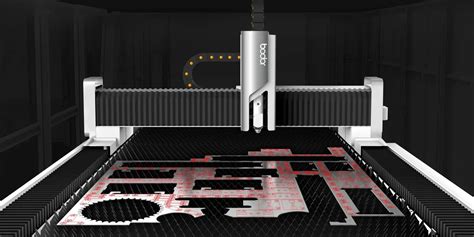

The Bodor plate fiber laser cutter provides efficient, high performance for large metal sheet cutting to guarantee high efficiency. Notable features include:

"One-second edge searching" ensures rapid material positioning and focus calibration using an optical camera to automatically identify the material's position and then locates its vertices and angular offset within 3 seconds.

"Visual collison avoidance" technology detects motions and signal warnings to prevent possible collisions.

"Active obstacle avoidance" technology detects potential obstacles like tilting parts and automatically avoids a potential collision to ensure stability as well as operating efficiency in the cutting process.

"One-click processing" allows the setup of tasks ahead of time, and once the operation begins, the cutting machine will automatically complete edge searching, range checking, and cutting one after another.

"Anti-burning mineral casting" allows material residue to automatically separate from the anti-burning plate, lowering mainteance costs and offering better durability.

"Lightning piercing technology" for rapid, precise piercing with reduced time.

"Intelligent remnant layout" to achieve maximum material utilization.

"Auto Focus" automatically adjusts the focal point in the cutting process to achieve the best cutting effect of different thickness sheet metal.

"Nesting software" enables auto nest up to 50 individual parts to ensure maximum efficiency and less waste.

This programmable pipe bender shapes material at blistering speeds with professional accuracy. It cuts down on time and effort for repeat projects by storing complex bend specifications as programs, and reduces delays with extremely fast automatic bending. Because it can accommodate a wide range of tooling, it is suitable for almost any application.

Tackles heavy-duty materials, bending up to 5” tubing and 4” schedule 80 pipe. Bend capabilities are 14 GA – 3/8.

Rotary draw bender smoothly executes 180° bends in just 20 seconds and can complete up to 360° bends.

Stores up to 170 programs of 10 bends each in its internal memory and accepts limitless external memory.

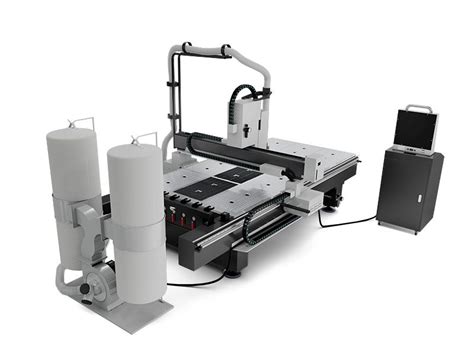

The Haas SR Series sheet router is an affordable alternative to gantry-style milling machines for cutting lighter, non-metallic materials, such as wood, plastics, high-density foam, and composites. This router provides a high level of programmability and functionality not found in other CNC routers. The SR-3015 is equipped with an 18,000-rpm ER32 collet spindle that accepts tools up to 0.75" (20 mm) diameter, and the machine’s large travels easily accommodate full sheets of material, long extrusions, or multiple setups of smaller parts. The intuitive Haas control interface and robust features make programming and adjustments easy.

Our brake press has a 130 ton capability with a 10’ bed.

Combining functionality and flexibility, this manual coating unit gives constant and reliable coating results for any powder coating: Polyester, Metallic, Fluoropolymer, and special effect powder coatings. It features closed loop air flow control (AFC) which continuously measures and corrects air pressure and volume ensuring precise and optimal coating results, and a fully electronic control unit enables quick and easy adjustment of coating parameters for reproducible results, and can save 50 coating recipes making it ideal for many color and object changes.

We have all the equipment necessary to handle heavy and hard to reach installations.